Types of Wire Cloth

- Woven Wire Cloth – The most common and is used for general sorting, screening and filtering applications.

- Welded Wire Cloth – Considered to have a smoother surface and can have larger open area and/or larger wire diameter. Intersecting wires are welded together at each junction. The welds provide more strength and rigidity to maintain a uniform cloth.

Both types of Wire Cloth can be effectively cut, formed and fabricated into various shapes to meet particular requirements or reach specific levels of filtration.

Materials

Types of Weaves (PDF-91KB)

PDF Wire Cloth Uses (PDF-53KB)

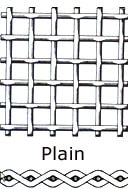

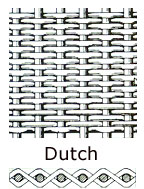

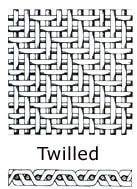

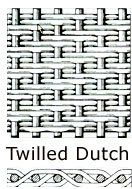

Types of Weaves

The Twilled Dutch Weave is produced by a combination of the features of the Dutch Weave and the Twilled Weave. Fill wires are passed alternately over and under two warp wires forming a fine mesh in one direction and a coarse mesh (mesh wire, woven wire mesh, wire mesh basket) in the other. This type of weave is capable of supporting greater loads than the Dutch Weave, with finer openings than the Twilled Weave. It is used in applications where the filtering of heavy material is necessary.Wire cloth (woven wire cloth, stainless steel wire cloth, wire cloth screen, wire cloth strainer, industrial wire cloth, metal cloth, wire cloth) is metal wire of various alloys that is woven or welded forming a cloth like material. Wire cloth can be formed in a variety of opening sizes and wire diameters. The open area is call mesh count or mesh per linear inch and is the critical information needed when ordering wire cloth.

Measuring Wire Cloth

| A: | Space Cloth identifies the open area between the parallel wires. |  |

| B: | Mesh Count identified as the number of openings per linear inch. |

Mesh count can be shown as either a whole number, fraction, or as two numbers unless the material is a specialty cloth called space cloth – each different item is described below:

- Whole Number or Fraction

Mesh Count is identified as the distance from center to center of the parallel wires horizontally and vertically. - Space Cloth

This material is measured by the actual open space between parallel wires, known as clear opening, space size, or open area. - Two Numbers (Example: 2 x 2 )

Mesh Count is identified by the number of actual openings per linear inch horizontally and vertically.

Mesh = 1 / (wire diameter + opening)

Open area = (opening x mesh)² x 100-Or-

= (1 – (wire diameter x mesh)² x 100mesh

-Or-

= (1 – (wire diameter x mesh))² x 100

Opening = (1 / # wires per inch) – (wire diameter)

Mm to inches: mm x 0.03937 = inches

Square feet: Length (feet) x Width (inches)12

How to Measure Wire Cloth

Coarse Mesh

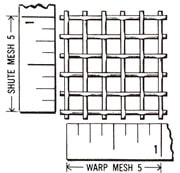

To measure wire cloth (woven wire cloth, stainless steel wire cloth, wire cloth screen, wire cloth strainer, industrial wire cloth, metal cloth, wire cloth) properly, the mesh count should be taken in both directions. On coarse meshes (mesh wire, woven wire mesh, wire mesh basket), this can be accomplished by counting the number of openings per linear inch measuring from wire center to wire center. After taking the first count, a second count should be taken at a 90 degree angle to the original measurement. The mesh count of the cloth shown is 10×10.

Fine Mesh

A mesh counter is used to measure finer meshes of wire cloth (woven wire cloth, stainless steel wire cloth, wire cloth screen, wire cloth strainer, industrial wire cloth, metal cloth, wire cloth) accurately. The fine mesh count is taken the same way the coarse mesh is computed by counting the number of openings per linear inch in one direction and taking another count at right angles to the original measurement.

Wire Diameter

Wire diameter is always checked with a micrometer. Diameters of wires in both directions should be checked.

Wire Cloth Uses

Although there are easily many uses for wire cloth, it is rarely seen. Industrial wire cloth is considered a component for equipment that has a need for filtering, separating, straining, sizing, diffusing, providing structure, etc.

- Architectural Design

- Electromagnetic Field (EMF) Shielding

- Low NOx Applications

- Heat Conductor – Roof / Gutters

- Medical (ie. Stints)

- Straining

- Diffusion – Liquid, Gas

- Sizing of crush material

- Explosive testing

- Dredging

- EMI/RFI Shielding

- Fuel Cells

- Filtration – Liquid / Gas

- Gas Burners

- Safety and Protection

- Baskets for dipping

- Structure

- Blast Containment

If you’d like to learn more about the various types of wire cloth, wire cloth uses, types of weaves, or how to measure wire cloth, please contact us today!